When to Forge and When to Machine

When your application requires a new or replacement part, there are a few metalworking processes to choose from. Each offers a unique set of pros and cons, depending on your needs, so it is important to understand your options.

Review the guide below for a better idea of when to forge and when to machine:

When to Forge

Forging offers many unique advantages when compared to machining, especially in demanding industrial applications. If you are worried about your parts failing prematurely, or your application requires maximum strength and durability, forging is likely better suited to your needs.

- To improve part integrity

Forging provides a higher level of structural integrity than any other metalworking process. By eliminating structural voids that can weaken parts, forging provides a level of uniformity to help maximize part performance.

- To keep grain flow intact

During machining, grain ends are exposed, making parts more susceptible to weakening and cracking. Forging refines and strengthens parts by keeping the grain flow intact, helping to strengthen transition points and prevent premature failures.

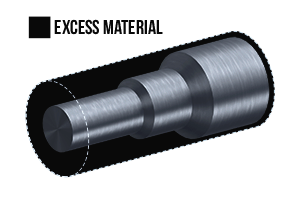

- For material savings

Because it requires less starting material to create a forged part, open-die forging can help reduce waste and material costs. When you turn a product from bar, the corner stock is lost, but you are still required to pay for the excess material. With open-die forging, your part is shaped by the dies, significantly reducing material waste.

When to Machine

While forging offers many advantages in part strength and longevity, it is not necessary for many lower-impact applications. If your parts will not be subject to ongoing wear and tear, machining will likely be an effective and affordable solution for your needs.

- For simpler applications

In lower-impact applications, strong transition points are likely not your top priority. Parts machined from bar are typically sufficient if you are planning to use your parts in less demanding environments.

- If the budget is tight

Forging can be a pricier alternative to machining, and although it offers many benefits, these benefits might not outweigh the costs in some situations. If the longevity and material savings from forging do not compensate for the price tag, machining might make more sense for your application.

What is Open-Die Forging?

Not sure what we mean by open-die forging? You are not alone. Open-die forging is a process of shaping steel without the use of part-specific dies, allowing for complete customization. Forging is one of the best ways to create durable metal parts, built to stand up to tough industrial applications.

Whether forging or machining is best suited to your needs, Solmet has the skills, equipment and capabilities to take on your next project. Request a quote using the form below to get started.