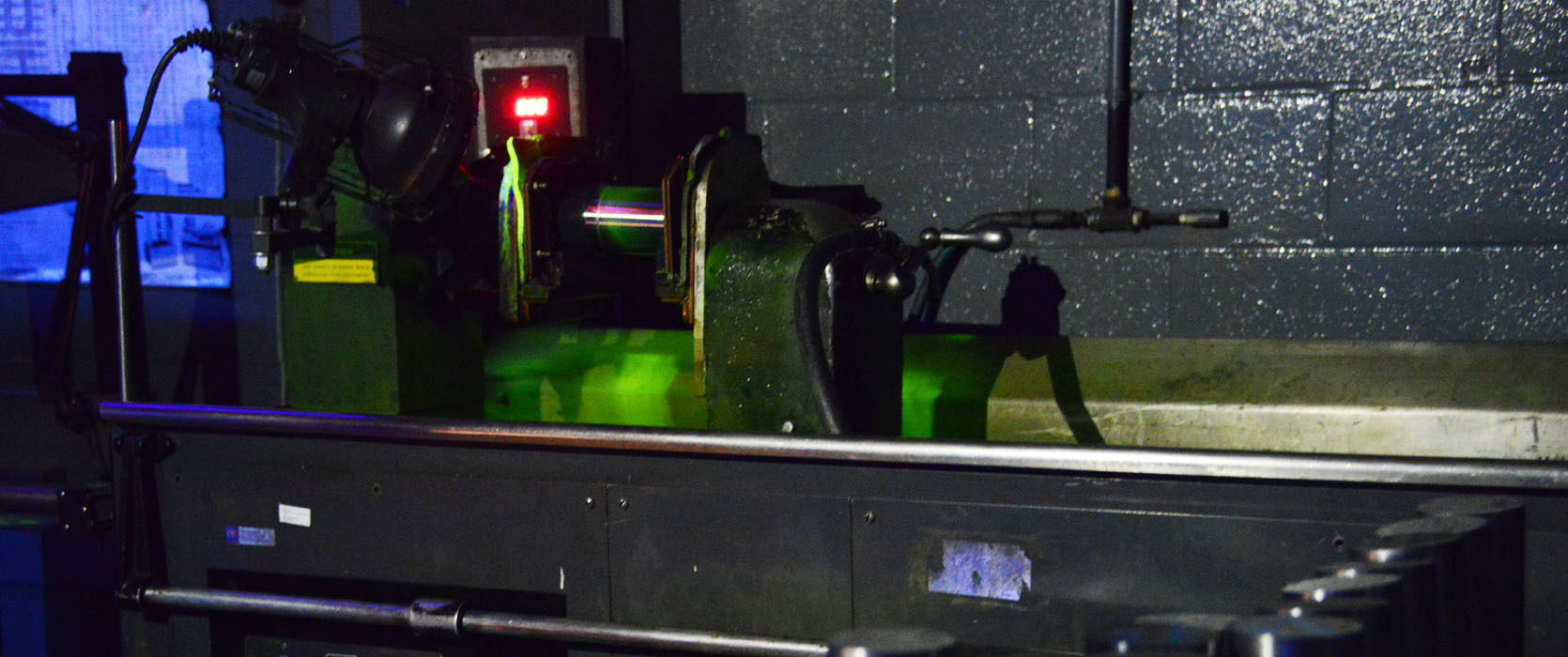

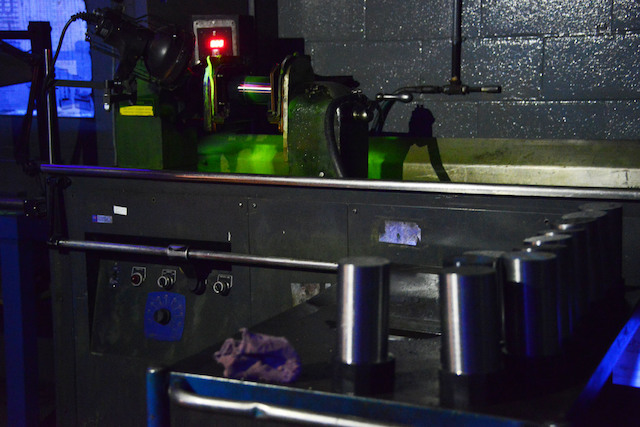

Magnetic Particle Inspection

The magnetic particle testing method is used to detect cracks, laps, seams, inclusions, and other discontinuities on or near the surface of ferromagnetic materials. Magnetic particle testing may be applied to raw material, billets, finished and semi-finished materials, welds, and in-service parts.

About Magnetic Particle Inspection

Magnetic particle testing consists of magnetizing the area to be examined, applying suitably prepared magnetic particles while the area is magnetized, and subsequently interpreting and evaluating any resulting particle accumulations. Maximum detectability occurs when the discontinuity is positioned on the surface and perpendicular to the magnetic flux.

Solmet Technicians are fully certified to perform examinations in accordance with ASTM E1444. We offer in-house or on-site testing. Solmet Technicians are qualified and certified in accordance with ASNT Recommended Practice No. SNT-TC-1A, ANSI/ASNT Standard CP-189, NAS 410, or as specified in the contract or purchase order from Solmet’s customers.

Benefits of Magnetic Particle Inspection

- Quick and efficient process

- Immediate results and certified test reports

- Detects surface and subsurface defects

- Cost effective

- Can be performed on a variety of designs and dimensions

Solmet Capabilities

Solmet Magnaflux Full Wave DC (FWDC) machines use the wet, continuous magnetic particle inspection method described in ASTM E1444. Solmet also offers testing to ASTM E1444 dry method which uses powder and either AC or DC contact probes.