CNC Machining

Are you looking for quality machined parts at competitive prices? With state-of-the-art equipment built to accommodate virtually any material, Solmet is the top choice for your machining needs.

Our machinists work with efficiency and precision to deliver your custom machined parts on time and on budget. We have the capabilities to serve as your one-stop-shop, taking care of everything from machining, heat treating, and non-destructive testing. Our machinist are also well experienced in machining raw forgings. No job is too large or too small, and we work to understand and deliver on your custom project requirements.

Why CNC machining?

Through our quick, affordable machining services, we machine parts with diameters up to 64” and lengths up to 156”.

Experience the Solmet Difference. We are proud to offer state-of-the-art equipment, quick turnaround times, and material and cost savings. You can count on us for precision, durability and efficiency.

Our commitment to our customers, employees and community is one of the main reasons different industries in the Canton, Ohio, area and beyond choose to work with us.

Capabilities

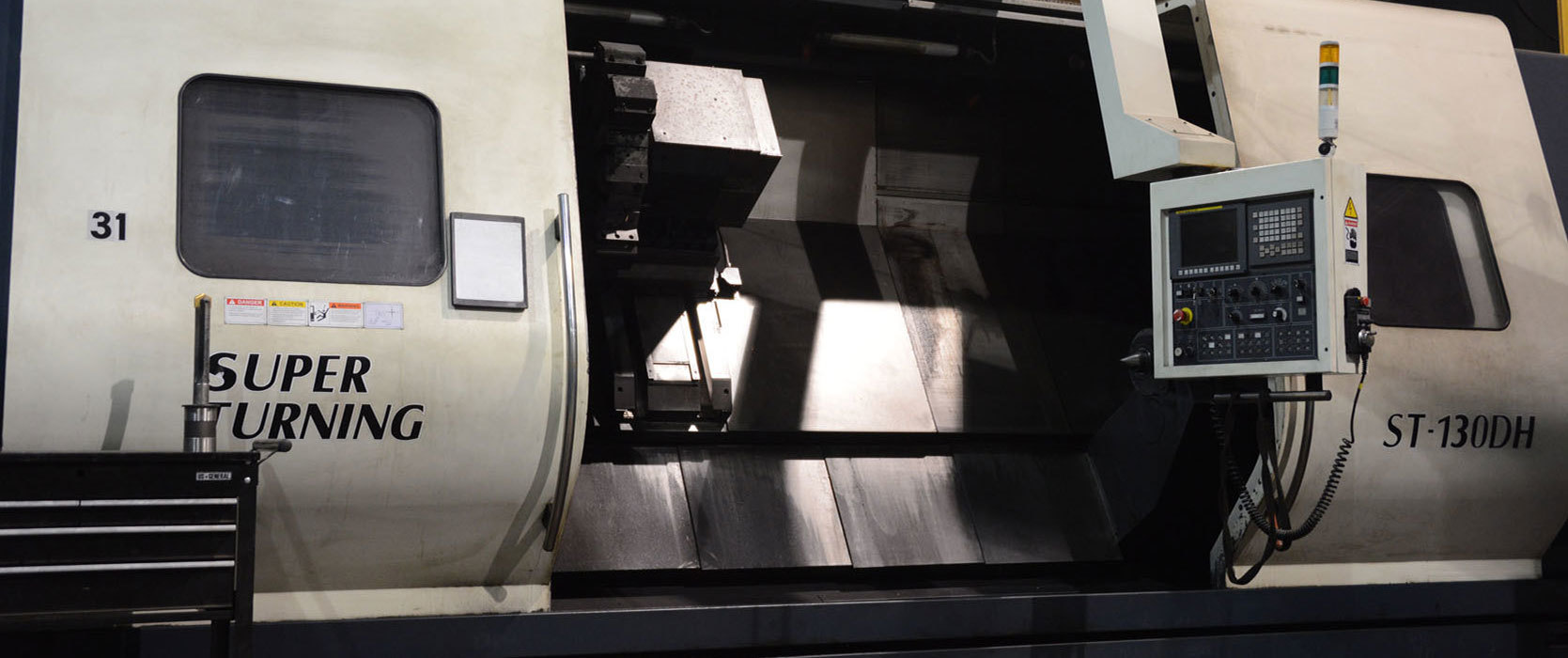

CNC Machining

From made-to-order prototypes to low-volume production runs, Solmet is equipped to handle your CNC machining needs. Our VTL (Vertical Turret Lathe), horizontal lathes and machining centers are designed for maximum efficiency and speed, offering affordable machining with quick turnaround times. Our state-of-the-art equipment is built to accommodate virtually any material.

Solmet’s finish CNC machining services ensure your parts will meet the tolerance and surface finish requirements you demand. We take care of your project from start to finish, including forging, machining, deep hole drilling, heat treating, testing (non-destructive and mechanical) and supply chain management.

With a focus on precision and accuracy, Solmet is a top provider of finish CNC machining for many industries and applications.

Machining of Raw Forging

After coming off the forging hammer, parts have a rough, black-as-forged finish that can be difficult to machine. We machine our forgings to the tolerances you demand, providing a near-net shape ready for finish. Whether you require a rough-turned part or a turnkey solution, we have the capabilities to meet your needs.

4-Axis Machining

Our machinists operate state-of-the-art 4-axis CNC lathes for optimal tool path effectiveness and programming speed, allowing for the machining of complex shapes.

Metal Cutting

Our custom and production cut shop directly feeds our forge and machine shops, offering all the services required to manage your project from start to finish. We specialize in large billet, bar, tubing and non-standard shapes up to 24”.

With state-of-the-art-equipment and more than 35 years of experience, our metal cutting team has the necessary tools and skills to meet the needs of your low- to mid-volume production runs.

Specifications

| CNC Lathes | 4-Axis CNC Lathes | VTL (Vertical Turret Lathe) | CNC Machining Centers |

| Max Swing: 27.5" | Max Swing: 21.25" | Max Table Diameter: 64" | X: 32”/ Y: 20”/ Z: 24” |

| Between Centers: 120" | Between Centers: 85" | Clearance under rail: 60" | Table - W: 20” |

| Spindle Bore: 6.5" | Spindle Bore: 4.5" | Table – L: 40” |

Materials

We work with a wide variety of metals and plastics so you can find exactly what you need. And when you can’t? We can provide custom materials as well.

- Steel: Alloy, Carbon and Stainless

- Aluminum

- Brass

- Bronze alloys

- Copper

- Magnesium

- Nickel

- Plastics, including acrylic, HDPE, nylon, polycarbonate, Teflon and PVC

- Titanium

- Tool Steel

- Zinc

- Custom abilities

Industries

- Aerospace

- Automotive

- Agriculture

- Energy, including oil and gas

- Job Shop Machining

- Machine Rebuild

- Material Movement

- Medical

- Marine

- Steel Production

- Subsea

Watch: Solmet Machining Facility

Hear from a satisfied customer...

"The customer service has been great. They are looking out for us and for our best interest. Anytime we have questions, they have been wonderful. Turnaround times are very short, and we’re not left wondering if the message is received." - Chris Kaboth, Whitacre Greer Vice President of Operations

Certifications

ISO 9001:2015 | API Q1

At Solmet, we strive to create a safe workplace made up of a highly trained, certified staff. We are proud of our many memberships and associations within the forging industry and throughout our community.

Request a Quote

Request a quote today by filling out the form below and a member of our team will reach out to you to discuss your CNC machining needs.